Are you wondering why your puff vinyl is wrinkling? We’ve got the answers you need.

In this article, we’ll delve into the world of sublimation printing and the properties of puff vinyl. We’ll explore the factors that contribute to wrinkling and provide tips to troubleshoot this issue.

From temperature and time considerations to proper substrate selection, we’ve got you covered. Get ready to learn how to keep your puff vinyl looking smooth and flawless.

Sublimation Printing and Puff Vinyl

We have found that sublimation printing can cause the puff vinyl to wrinkle. Sublimation printing is a popular technique used to transfer designs onto various materials, including puff vinyl. The process involves using heat to turn the ink into a gas, which then permeates the fabric and solidifies, resulting in vibrant and durable prints.

However, when sublimation printing isn’t done correctly, it can lead to issues with the puff vinyl. One common problem is that the heat from the sublimation process can cause the puff vinyl to shrink and wrinkle. This can be frustrating, especially when you’ve put in a lot of effort into creating a design.

To troubleshoot this issue, it’s important to ensure that the puff vinyl is properly adhered to the fabric before sublimation. Make sure to use a high-quality adhesive that’s designed for use with puff vinyl. Additionally, adjust the heat and pressure settings on your sublimation machine to prevent excessive heat exposure, which can cause the vinyl to shrink.

Understanding the Properties of Puff Vinyl

To understand the properties of puff vinyl, let’s explore its unique characteristics and how they contribute to its wrinkling.

Puff vinyl is a type of heat transfer material commonly used in garment decoration. It’s known for its ability to create a raised, three-dimensional effect on fabrics.

Here are the key properties of puff vinyl:

- Thickness: Puff vinyl is thicker than regular vinyl, which allows it to expand when heated, creating a puffed appearance.

- Heat activation: Puff vinyl requires heat to activate the adhesive and expand. Applying heat evenly and at the right temperature is crucial for achieving the desired puff effect.

- Adhesion: Puff vinyl has a strong adhesive backing that adheres well to various fabrics, ensuring durability and longevity.

- Flexibility: Despite its thickness, puff vinyl remains flexible and doesn’t crack or peel easily. This makes it suitable for applications on garments that require frequent stretching or movement.

- Durability: Puff vinyl is known for its durability. It can withstand multiple washes and is resistant to fading, cracking, and peeling.

Understanding these properties is essential for achieving successful puff vinyl application and ensuring its durability. By properly applying heat and choosing the right fabric, you can minimize the risk of wrinkling and ensure a long-lasting puff effect on your garments.

Factors That Contribute to Wrinkling in Puff Vinyl

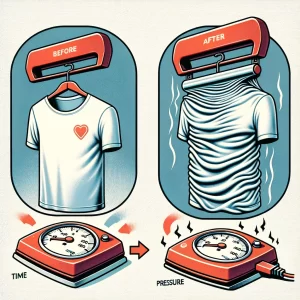

Although there are several factors that contribute to wrinkling in puff vinyl, one of the main culprits is improper heat application. Common causes of puff vinyl wrinkling include uneven heat distribution, excessive heat, and inadequate pressure during the application process.

Uneven heat distribution occurs when heat isn’t evenly applied to the entire surface of the puff vinyl. This can result in some areas being underheated, causing wrinkling. Excessive heat can also lead to wrinkling as it can cause the vinyl to shrink and distort. Additionally, inadequate pressure during the heat application process can prevent the vinyl from adhering properly, resulting in wrinkles.

To prevent wrinkling in puff vinyl, it’s important to ensure proper heat application. This can be achieved by using a heat press that provides even heat distribution across the entire surface of the vinyl. It’s also crucial to use the appropriate temperature and pressure settings recommended by the manufacturer.

Furthermore, it’s essential to carefully follow the instructions provided by the manufacturer for the specific type of puff vinyl being used. This may include preheating the garment, using a Teflon sheet or parchment paper, and allowing sufficient cooling time before removing the carrier sheet.

Temperature and Time Considerations in Puff Vinyl Sublimation

During the process of puff vinyl sublimation, careful consideration of temperature and time is crucial. Achieving the right temperature and allowing sufficient time for the sublimation process are essential for obtaining high-quality results.

Here are some important factors to keep in mind:

- Puff vinyl sublimation techniques:

- Heat press temperature: Set the heat press to the recommended temperature range for puff vinyl sublimation. This ensures that the vinyl expands and puffs up properly.

- Dwell time: The duration the heat press applies pressure and heat to the vinyl is critical. Sufficient dwell time allows the sublimation process to occur fully and ensures the vinyl maintains its puffiness.

- Common mistakes in puff vinyl sublimation:

- Insufficient temperature: If the heat press temperature is too low, the vinyl may not expand or puff up properly, resulting in a less desirable outcome.

- Inadequate dwell time: Failing to give the vinyl enough time under heat and pressure can lead to incomplete sublimation and a less pronounced puff effect.

Proper Substrate Selection for Puff Vinyl Sublimation

When considering proper substrate selection for puff vinyl sublimation, it’s important to regularly assess the compatibility of the material with the sublimation process. Substrate options play a crucial role in achieving successful and wrinkle-free puff vinyl sublimation results. The first factor to consider is the composition of the substrate. Synthetic materials such as polyester are ideal for puff vinyl sublimation as they’ve a high affinity for dyes and allow for vibrant color transfer. Natural fibers like cotton, on the other hand, may not provide the same level of color vibrancy or durability.

Another important consideration is the color selection of the substrate. Light-colored substrates are generally recommended for puff vinyl sublimation, as darker colors can affect the visibility and contrast of the design. However, if using dark-colored substrates is necessary, a white base layer can be applied to enhance the colors and increase the visibility of the design.

It is also essential to consider the texture and smoothness of the substrate. Rough or textured surfaces may not provide an even transfer of the puff vinyl ink, leading to inconsistencies in the design. Smooth and flat substrates, such as polyester fabrics or ceramic tiles, provide optimal results for puff vinyl sublimation.

Preparing Artwork for Puff Vinyl Sublimation

To continue our discussion on proper substrate selection for puff vinyl sublimation, let’s now focus on preparing artwork for this process. Artwork design plays a crucial role in achieving high-quality and long-lasting results. Here are some key points to consider when preparing artwork for puff vinyl sublimation:

- Vector Format: Convert the artwork to a vector format, such as Adobe Illustrator (AI) or Scalable Vector Graphics (SVG). This ensures that the design can be scaled without losing quality and allows for easy manipulation of elements.

- Simplify Design: Keep the design simple and avoid intricate details or tiny text. Puff vinyl tends to expand during the sublimation process, so fine details may not transfer accurately.

Heat Press Techniques:

- Proper Temperature and Pressure: Set the heat press to the recommended temperature and pressure for puff vinyl sublimation. This ensures that the vinyl adheres well to the substrate and the design retains its puffiness.

- Preheat the Substrate: Preheating the substrate before applying the puff vinyl helps to eliminate moisture and improve adhesion.

Troubleshooting Tips for Wrinkling in Puff Vinyl Sublimation

When troubleshooting wrinkling in puff vinyl sublimation, it’s important to consider the heat press temperature and sublimation time duration. Adjusting the heat press temperature can help prevent excessive wrinkling, as higher temperatures can cause the vinyl to shrink and wrinkle.

Similarly, ensuring the correct sublimation time duration is used is crucial, as too long of a time can also lead to wrinkling.

Heat Press Temperature

To troubleshoot wrinkling in puff vinyl sublimation, we adjust the heat press temperature. Proper heat press settings are crucial in achieving smooth and wrinkle-free results.

Here are some troubleshooting techniques related to heat press temperature:

- Temperature too high:

- Reduce the heat press temperature gradually to avoid scorching the vinyl.

- Experiment with lower temperatures to find the optimal setting for your specific vinyl and substrate combination.

- Temperature too low:

- Increase the heat press temperature to ensure proper activation of the vinyl.

- Use a heat press temperature guide provided by your vinyl manufacturer for accurate settings.

Sublimation Time Duration?

Continuing our troubleshooting techniques for wrinkling in puff vinyl sublimation, let’s now address the sublimation time duration and its impact on achieving smooth and wrinkle-free results.

The sublimation time duration refers to the amount of time required for the sublimation ink to fully transfer onto the puff vinyl. It’s crucial to find the right balance between too short and too long of a sublimation time.

If the sublimation time is too short, the ink may not fully penetrate the puff vinyl, resulting in poor adhesion and potential wrinkling. On the other hand, if the sublimation time is too long, the puff vinyl may become overheated, leading to distortion and wrinkling.

To prevent puff vinyl wrinkling, it’s essential to follow the recommended sublimation time duration specified by the manufacturer and consider the type of sublimation ink used. Conducting test prints and adjusting the sublimation time accordingly can help achieve optimal results.

Frequently Asked Questions

What Is Sublimation Printing and How Does It Relate to Puff Vinyl?

Sublimation printing is a technique that allows for vibrant and durable designs on various materials. Puff vinyl, when used in sublimation printing applications, adds dimension and texture to the final product, enhancing its visual appeal.

What Are the Properties of Puff Vinyl and Why Is It Prone to Wrinkling?

The properties of puff vinyl include a raised, three-dimensional effect and a soft texture. However, it is prone to wrinkling due to its thickness. To prevent wrinkling, avoid excessive heat and pressure during application.

What Factors Contribute to Wrinkling in Puff Vinyl?

To prevent wrinkling in puff vinyl, avoid excessive heat and pressure during application. Also, ensure proper curing time and avoid overstretching the material. Common mistakes include applying too much pressure or heat, and rushing the curing process.

How Does Temperature and Time Affect Puff Vinyl Sublimation?

When using puff vinyl sublimation techniques, it’s important to consider the effects of temperature and time. Higher temperatures and longer exposure times can cause wrinkling in puff vinyl. Troubleshooting this issue requires adjusting these variables for optimal results.

What Is the Importance of Selecting the Proper Substrate for Puff Vinyl Sublimation?

When it comes to puff vinyl sublimation, proper substrate selection is crucial. The right substrate ensures optimal adhesion and prevents wrinkling. Choose a substrate that is compatible with the puff vinyl and can withstand the heat and pressure of the sublimation process.

Conclusion

In conclusion, wrinkling in puff vinyl sublimation can occur due to several factors. These include incorrect temperature and time settings, improper substrate selection, and inadequate preparation of artwork.

By understanding the properties of puff vinyl and following proper sublimation techniques, such as adjusting temperature and time settings and selecting suitable substrates, one can minimize wrinkling issues.

Additionally, troubleshooting tips can help address any wrinkling problems that may arise during the sublimation process.