Do you love personalizing everyday items like phone cases or water bottles with unique designs? Sublimation printing is a great way to bring your creativity to life!

However, you may have wondered “can you sublimate on plastic materials?”

The thought of creating your own custom plastic items may seem too good to be true, but it is possible with the right techniques.

In this article, we’ll dive into the world of sublimating on plastic and show you everything you need to know.

Can You Sublimate on Plastic?

Yes, you can sublimate on plastic! In fact, sublimating on plastic opens up a whole world of customization possibilities. You can create one-of-a-kind phone cases, personalized water bottles and custom promotional products.

Also Read: Can You Sublimate on Modal Fabric?

However, not all plastics are created equal and you cannot sublimate on all of them. It only work well if the plastic contains a polyester-based material structure.

Sublimation ink bonds chemically with the polyester materials, thus producing a rich and long-lasting color.

It’s also worth noting that sublimating on plastic requires a slightly different process than sublimating on fabric.

What Type of Plastic Can You Sublimate On?

Some plastics are unsuitable for sublimation. The best types are the ones made using polyester-based materials.

Why? It’s because the ink reacts with the polyester well, which produces rich and long-lasting color results.

Furthermore, plastic items with a polyester coating or any polyester product are perfect for this process. Here is a small breakdown of the plastics you can sublimate on:

Polyester fabric: These are fabrics that feature polyester-based materials which work well for sublimation. You can find them in mugs, keychains, or even phone cases.

Polyester-based plastic materials: Some plastics are made using specialized polyester material and other materials. These plastics can undergo sublimation and often require specific temperatures or heat-pressing procedures.

Also Read: Sublimating On Nylon

Polyester-coated plastics: These plastics feature polyester coating, which works well for sublimation procedures.

How to Sublimate on Plastic

Here’s a step-by-step guide to sublimating onto plastic using heat transfer:

Items Required

- Plastic surface.

- Sublimation Ink.

- Sublimation paper.

- Heat-resistant tape.

- Heat press machine or iron, one with heat control settings.

- Protective gloves.

- Protective paper or Teflon sheet.

Steps

Here are the steps involved in plastic sublimation:

Step #1: Design your Image

Pick the design you want to sublimate on the plastic surface. Ensure you pick the correct design size to match the surface you picked.

Step #2. Printing the Design

You must then print the design on your sublimation paper using specialized ink. We also recommend you go for a printer that can support the sublimation process.

Also Read: Can You Mix Sublimation Ink Brands?

Step #3. Prepare the heat press

If you use a heat press machine, set it to the correct temperature, and calibrate the pressure as required. It is an iron that calibrates its temperature to suit the sublimation process.

Step #4. Preheat the Press or Iron

The next step is to let the heat press or iron heat up to the required results. Doing this ensures the plastic surface is warm and suitable for the sublimation process.

Step #5. Secure the Design

Place the plastic tool on a heat-resistant surface. Next, align the printed sublimation paper with a plastic surface. Use heat-resistant tape to secure the design to the surface. Ensure you also set the design such that it’s facing the plastic.

Step #6. Apply the Heat and Pressure

If you use a heat press, close it to the plastic surface and let it sit over it for a few minutes.

The general rule for plastic sublimation is to use temperatures between 350°F to 400°F (175°C to 205°C). The average pressing time should also be between 30 to 90 seconds for the best results.

Step #7. Remove the Heat and Pressure

Once the heat press process is complete, remove it from your printing surface. Be careful now because the paper and plastic might be hot. Let it cool down for a few minutes before checking the design.

Step #8. Peel of the Paper

Remove the sublimation paper from the plastic surface gently and carefully. To stop design damage complications, ensure you peel it slowly, preferably at a low angle.

Step #9. Examine the Plastic Surface

Evaluate the plastic surface to ensure the design transfer process completes as required. You will notice crisp and vibrant colors on the surface if you complete it as required.

PRO TIP! The specificity of each sublimation process varies depending on the resources and materials you used. Ensure you adhere to the instructions of your manufacturer for the best results. You must also use high-quality paper and resources for this process.

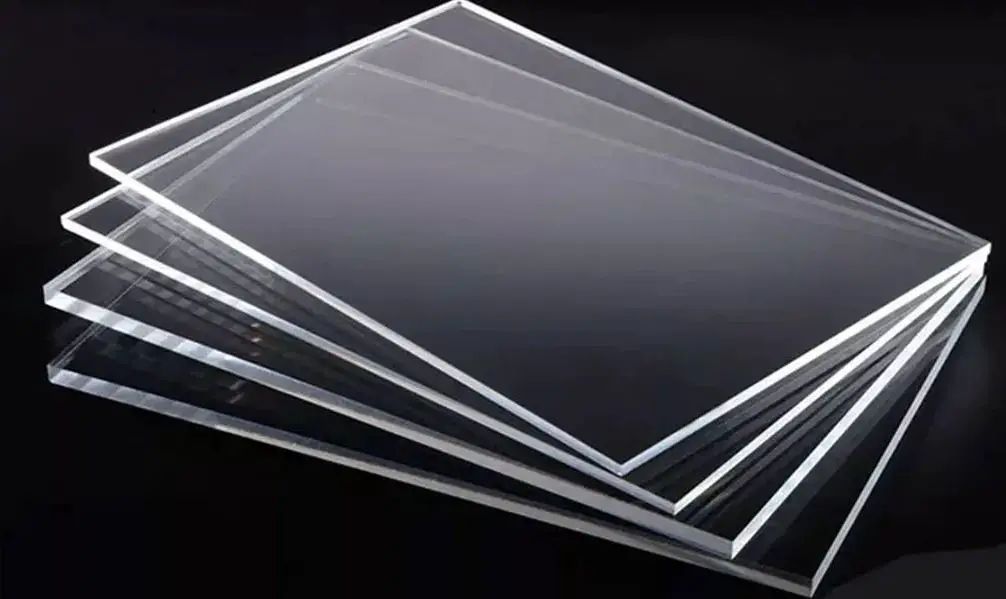

Can You Sublimate on Acrylic Plastic?

Unfortunately, it’s not possible to sublimate on acrylic plastic. Acrylic is a thermoplastic product that doesn’t have the right polyester content to work well with sublimation inks.

Remember that sublimation requires the ability of ink to bond with materials such as polyester fibers. This then allows the transfer of the design onto the material.

However, it’s also possible to sublimate onto acrylic surfaces indirectly.

One technique many people use for this process involves dye sublimation transfer. It involves printing the design onto the sublimation paper using specialized ink.

The user must then heat press the ink onto a polyester-coated transfer sheet. The sublimation plastic sheet is then set on the acrylic surface using heat-activated glue or a specialized adhesive.

However, the result of this process might be of the same quality or longevity as sublimating to polyester-based materials. We also recommend you check the recommendations of manufacturers for the best results.

Frequently Asked Questions (FAQ)

What Materials Can You Not Sublimate On?

There are various materials that you need help to sublimate on. These include natural fabrics, ceramics, and non polyester fabrics. Materials that can’t stand a heat press also won’t work for this process.

What Temperature Do You Sublimate Plastic?

The best temperature for sublimation on plastic is 400 degrees Fahrenheit for up to 60 seconds. You must also observe the heating process for the best results. Check the heat press settings twice before you start each process.

Can You Sublimate on Corrugated Plastic?

No, it’s not possible to sublimate on corrugated plastic. Even if it was possible, this process requires various complex variables that can be difficult to manage. You should instead find better alternatives to printing, and they are many.